United States, New York, Oct. 24, 2024 (GLOBE NEWSWIRE) — Food Extrusion Market is a vital process in the food industry, involving the transformation of raw ingredients into shaped and textured products through a controlled method of cooking and shaping. This technique employs a system where mixed ingredients are propelled through a die, resulting in what are known as extrudates. Initially developed for processing meats and sausages using piston and ram-type extruders, food extrusion has evolved to encompass a wide range of applications, including breakfast cereals, confectionery items, baby foods, and various pasta types.

The food extrusion process not only enhances the quality and safety of food products but also significantly contributes to the efficiency of food manufacturing. By subjecting ingredients to high temperatures, extrusion effectively reduces microbial loads and eliminates natural toxins, making food safer for consumption. Additionally, the process is characterized by its high productivity, versatility, energy efficiency, and cost-effectiveness. These attributes allow for the production of a diverse array of food products while minimizing space requirements in manufacturing facilities.

The global food extrusion market has experienced substantial growth and is projected to continue this trend. In 2023, the market was valued at approximately US$76.74 billion and is anticipated to reach US$113.06 billion by 2032, representing a significant increase during the forecast period from 2024 to 2032. This growth is driven by rising consumer demand for convenient and processed food options, along with innovations in extrusion technology that enhance product quality and variety.

The COVID-19 pandemic has further accelerated the shift towards processed food as consumers seek long-shelf-life products that are easy to prepare and consume. The extrusion process facilitates the creation of products that meet these consumer preferences, positioning it as a crucial component of the food supply chain.

Key players in the food extrusion market are continually investing in research and development to improve extrusion techniques and expand product offerings. The focus is not only on traditional applications but also on developing novel ingredients and formulations that cater to evolving consumer tastes and dietary needs.

Download Sample 250 Pages of Food Extrusion Market Report@ https://introspectivemarketresearch.com/request/15903

Rising Demand for Textured Proteins Fuels Growth in the Food Extrusion Market

The rising demand for textured protein is significantly reshaping the food extrusion market, making it a vital driver of growth. As the global population increasingly embraces sustainable diets, including veganism and vegetarianism, the need for textured protein has surged. This shift is particularly evident among health-conscious consumers and those seeking alternatives to traditional meat products. Textured proteins, which are often made from soy, pea, or wheat, have gained popularity due to their versatility and ability to mimic the texture and flavor of meat. Consequently, the meat alternative market is experiencing robust growth, further fueled by the advancements in food extrusion technology that enhance the production of these proteins.

The food extrusion process plays a critical role in creating textured proteins, as it allows for the denaturation of proteins, which improves their nutritional profile and functional properties. This transformation not only enhances the sensory attributes of meat alternatives but also expands their culinary applications, making them more appealing to a broader audience. Moreover, food extruders are instrumental in maintaining the quality and safety of extruded products by effectively removing microorganisms and natural toxins, thereby ensuring safer consumption.

Additionally, the changing lifestyles of consumers, marked by busier schedules and increased disposable incomes, are driving demand for ready-to-eat food products. The convenience offered by extruded snacks and meals caters to the fast-paced lives of modern consumers who prioritize quick and nutritious options. This trend is particularly pronounced in developing countries like India, Brazil, China, and the Middle East, where there has been a notable shift from traditional homemade meals to convenient ready-to-eat products.

Furthermore, the growing trend of snacking between meals is amplifying the demand for extruded snack types, contributing to the overall expansion of the food extrusion market. As industrialization and globalization continue to shape consumer preferences, the food extrusion market is poised for significant growth, driven by the evolving needs and desires of consumers worldwide.

Emerging Opportunities in the Global Food Extrusion Market through Innovation, Health Trends, and Untapped Markets

The global food extrusion market is witnessing substantial growth driven by several key factors, creating lucrative opportunities for both established and emerging players in the industry. One of the most significant advancements is the continuous innovation in the development of extruded food products. As consumer preferences evolve, the demand for novel, convenient, and nutritious food options is on the rise. Food extrusion technology allows manufacturers to create a wide array of products, from snacks to ready-to-eat meals, meeting the diverse tastes and dietary needs of consumers. This technological evolution not only enhances product quality but also broadens the range of flavors and textures available in the market.

Moreover, government initiatives and investments aimed at bolstering the processed food sector have further catalyzed growth in the food extrusion market. Many governments recognize the importance of food security and nutrition, leading to increased funding for food processing technologies. These initiatives promote the adoption of extrusion technology, thereby improving food safety, quality, and accessibility in various regions. This supportive regulatory environment fosters innovation and encourages new entrants to explore opportunities within the market.

Additionally, there is a significant untapped potential in developing markets. As urbanization increases and disposable incomes rise in these regions, consumers are becoming more receptive to processed and extruded food products. The growing trend of health consciousness, particularly due to sedentary lifestyles and the increasing prevalence of lifestyle diseases, has led to a heightened demand for “healthy” snacks and fortified food items. This shift in consumer behavior presents a ripe opportunity for companies to develop extruded snacks that are not only delicious but also nutritious, catering to the health-oriented consumer base.

Do you need any industry insights on Food Extrusion Market, Make an enquiry now >>? https://introspectivemarketresearch.com/inquiry/15903

Fluctuating Raw Material Prices Are A Key Restraint in The Food Extrusion Market

The food extrusion market faces several significant restraints and challenges that hinder its overall growth potential. One of the most pressing issues is the fluctuating prices of raw materials, which can create unpredictability for manufacturers. The cost of essential ingredients, such as wheat and vegetable oil, can vary dramatically—sometimes exceeding 40%. This volatility makes budgeting and forecasting challenging for companies in the food extrusion sector, leading to increased operational costs and reduced profit margins.

In addition to raw material costs, stringent food regulations pose another barrier to growth. Regulatory bodies around the world enforce strict standards regarding food safety, quality, and labeling. While these regulations are essential for consumer protection, they can be cumbersome and costly for food extrusion companies to navigate. Compliance with these regulations often requires significant investment in quality control measures and testing, further impacting profitability.

Moreover, global climatic changes have a profound effect on the availability and quality of raw materials. Adverse weather conditions, such as droughts, floods, and temperature fluctuations, can lead to reduced agricultural yields. This not only restricts the supply of crucial inputs for food extrusion but also drives up prices due to scarcity. The impact of climate change can also influence the nutritional quality and characteristics of raw materials, complicating the extrusion process and affecting end product quality.

Furthermore, the high costs of specialized ingredients for snack pellet production, such as binding agents and savory flavors, also act as a restraint. These ingredients are essential for creating appealing and marketable food products but can be prohibitively expensive, leading to higher retail prices that may deter consumers.

Key Manufacturers

Market key players and organizations within a specific industry or market that significantly influence its dynamics. Identifying these key players is essential for understanding competitive positioning, market trends, and strategic opportunities.

- Brabender GmbH & Co. KG (Germany)

- Mondelez International and Universal Robina. (US)

- Bühler (Switzerland)

- Akron Tool & Die (US)

- Jinan Darin Machinery Co.

- Groupe Legris Industries (Belgium)

- Lindquist Machine Corporation (USA)

- Baker Perkins (UK)

- Coperion (Germany)

- GEA (Germany)

- KAHL Group (Germany)

- Triott Group (Netherlands)

- Flexicon (US)

- Kahl Group (Germany)

- The Bonnot Company (US)

- Pavan SPA(Italy)

- American Extrusion International (US)

- Shandong Light M&E Co.Ltd (China)

- Snactek (India)

- Doering Systems Inc. (US)

- PacMoore (US)

- Egan Food Technologies (US)

- Schaaf Technologie GmbH (Germany)

- Wenger Manufacturing Inc. (US) and other major key players.

In September 2024, Bühler, the Swiss technology group, announced the successful acquisition of Esau & Hueber, a German company renowned for its expertise in hygienic process and fermentation technology across the beverage, food, pharmaceutical, and biotechnology sectors. This strategic acquisition enhanced Bühler’s capabilities in malting, brewing, and sustainable protein solutions. By integrating Esau & Hueber’s innovative technologies, Bühler significantly expanded its expertise and capacity in these key areas. Additionally, the acquisition enabled the multiplication of Esau & Hueber’s technologies throughout Bühler’s extensive global network, further solidifying the company’s commitment to advancing sustainable practices in the industry. This move positioned Bühler as a leader in providing tailored solutions that meet the evolving demands of its customers in various sectors. The acquisition represented a significant milestone in Bühler’s growth strategy and reinforced its dedication to innovation and sustainability in food and beverage processing.

In August 2023, Anton Paar announced the acquisition of Brabender GmbH & Co. KG, effective retroactively. This strategic acquisition integrated Brabender into the Anton Paar Group as Anton Paar TorqueTec GmbH. Headquartered in Duisburg, Germany, Brabender specializes in measurement and process engineering solutions, providing advanced testing capabilities for various raw materials. Their expertise spanned diverse applications, including food, feed, plastics, rubber, batteries, and other specialized sectors.

This integration enhanced Anton Paar’s commitment to delivering cutting-edge solutions for recipe and process development, further strengthening its position as a leader in laboratory and process analytics. The collaboration promised to foster innovation and provide enhanced value to customers worldwide, combining Anton Paar’s renowned technological prowess with Brabender’s specialized capabilities.

If you require any specific information that is not covered currently, we will provide the same as a part of the customization >> https://introspectivemarketresearch.com/custom-research/15903

Key Segments of Market Report

By Product Type:

The cereals product segment is a dominant force in the food extrusion market, capturing a significant market share due to its widespread popularity and continuous innovation. As a staple for many households, breakfast cereals have evolved to include a variety of textures and flavors, appealing to diverse consumer preferences. The segment has seen the introduction of numerous product designs, enhancing its appeal and market reach.

One of the notable trends within this segment is the rise of granola and muesli mixes, which incorporate extruded cereals alongside nutritious components like nuts and raisins. This combination not only provides health benefits but also caters to the growing consumer demand for wholesome, convenient breakfast options. The versatility of extruded products allows for endless possibilities, enabling manufacturers to create unique blends that attract health-conscious consumers.

While almost any cereal can be processed using extrusion, functional cereals primarily include corn, wheat, and rice. Ready-to-eat cereals are typically modified through various processes such as flaking, puffing, shredding, extruding, and toasting. This ability to innovate and adapt to market trends solidifies the breakfast cereals segment as a leading player in the food extrusion industry, ensuring its continued growth and relevance in the market.

By Extruder:

The twin-screw extruder segment is poised to dominate the food extrusion market during the forecast period due to its numerous advantages over single-screw extruders. One of the primary factors contributing to this trend is the superior control of process parameters that twin-screw extruders offer. This capability allows for precise adjustments in temperature, pressure, and feed rates, resulting in consistent product quality and enhanced operational efficiency.

Moreover, the high level of process flexibility provided by twin-screw extruders is a significant draw for stakeholders in the food extrusion industry. These machines can easily handle a diverse range of raw materials, including grains, legumes, and other additives, making them ideal for producing various food products. The ease of functionality further simplifies operations, leading to reduced training costs and a quicker ramp-up time for new operators.

Cost considerations also play a crucial role in the segment’s growth. Twin-screw extruders typically exhibit less wear on smaller machine parts compared to their single-screw counterparts, resulting in lower maintenance costs and longer equipment lifespan. As a result, manufacturers are more inclined to invest in twin-screw technology, anticipating higher returns on investment and improved production outcomes.

By Region:

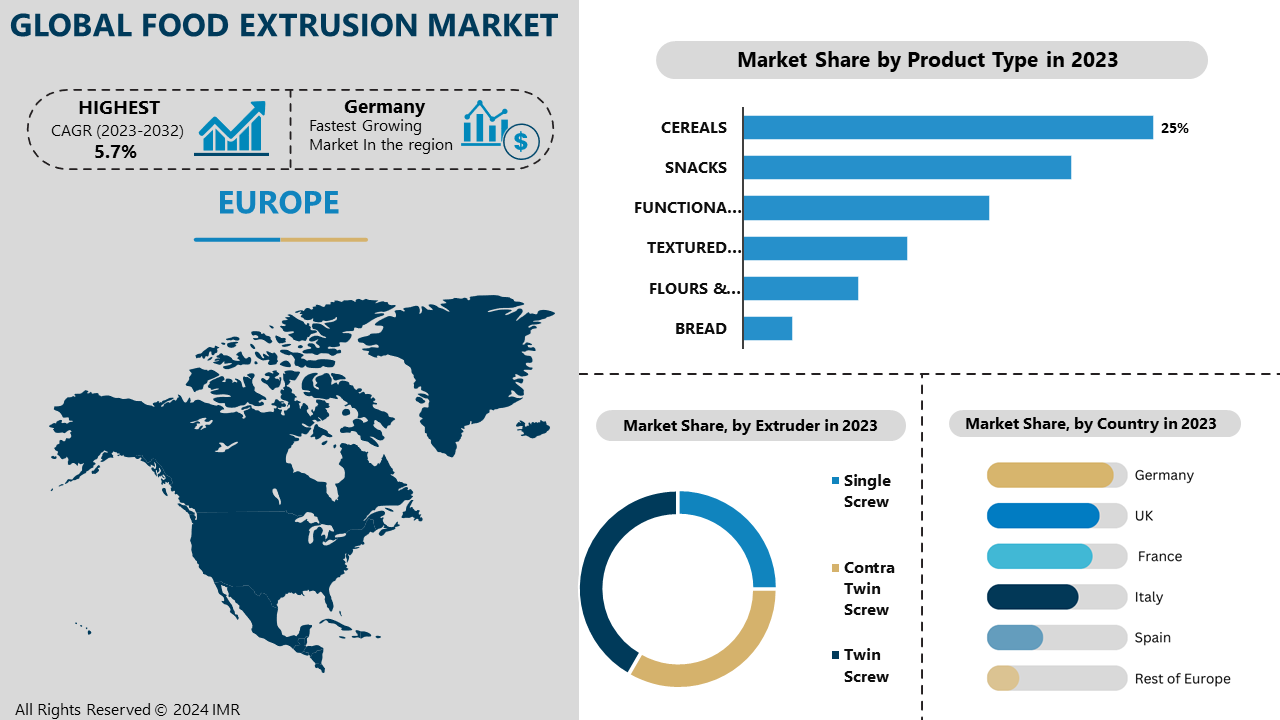

Europe is poised to maintain its dominance in the food extrusion market, fueled by a robust food and beverages industry. With a rich tradition of food production and innovation, Europe has established itself as a leader in the extrusion process, which enhances the texture and nutritional profile of various food products. This market trend is bolstered by consumer demand for innovative snack options, prompting manufacturers to explore new and diverse extruded product types.

Strict government regulations regarding food safety standards further strengthen Europe’s position in this market. These regulations ensure high-quality production processes and consumer safety, which are paramount in a region known for its culinary excellence. As a result, food producers are increasingly adopting extrusion technologies to meet these standards while enhancing product appeal. This commitment to quality and safety reinforces consumer trust and loyalty, driving the demand for extruded food products.

However, the domestic production of extruded snacks is struggling to keep pace with the growing demand from the food industry in Europe. To address this challenge, many producers are sourcing extruded snack products from international markets to ensure a steady supply of raw materials. This trend highlights the increasing interconnectedness of global supply chains and the importance of sourcing quality ingredients to meet the needs of European consumers.

Comprehensive Offerings:

- Historical Market Size and Competitive Analysis (2017–2023): Detailed assessment of market size and competitive landscape over the past years.

- Historical Pricing Trends and Regional Price Curve (2017–2023): Analysis of historical pricing data and price trends across different regions.

- Market Size, Share, and Forecast by Segment (2024–2032): Projections and detailed insights into market size, share, and future growth by segment.

- Market Dynamics: In-depth analysis of growth drivers, restraints, opportunities, and key trends, with a focus on regional variations.

- Market Trend Analysis: Evaluation of emerging trends that are shaping the market landscape.

- Import and Export Analysis: Examination of trade patterns and their impact on market dynamics.

- Market Segmentation: Comprehensive analysis of market segments and sub-segments, with a regional breakdown.

- Competitive Landscape: Strategic profiles of key players across regions, including competitive benchmarking.

- PESTLE Analysis: Evaluation of the market through Political, Economic, Social, Technological, Legal, and Environmental factors.

- PORTER’s Five Forces Analysis: Assessment of competitive forces influencing the market.

- Industry Value Chain Analysis: Examination of the value chain to identify key stages and contributors.

- Legal and Regulatory Environment by Region: Analysis of the legal landscape and its implications for business operations.

- Strategic Opportunities and SWOT Analysis: Identification of lucrative business opportunities, coupled with a SWOT analysis.

- Conclusion and Strategic Recommendations: Final insights and actionable recommendations for stakeholders.

Related Report Links:

Refractory Gunning Machine Market: Global Refractory Gunning Machine Market Size Was Valued at USD 19.86 Billion in 2023, and is Projected to Reach USD 37.92 Billion by 2032, Growing at a CAGR of 7.45 % From 2024-2032.

Smart Oil Dipstick Market: Global Smart Oil Dipstick Market Size Was Valued at USD 1.80 Billion in 2022, and is Projected to Reach USD 6.36 Billion by 2030, Growing at a CAGR of 17.10% From 2023-2030.

Industrial Centrifugal Pump Market: Global Industrial Centrifugal Pump Market Size Was Valued at USD 30.54 Billion in 2022 and is Projected to Reach USD 46.52 Billion by 2030, Growing at a CAGR of 5.40% From 2023-2030

CNC Routers Market: Global CNC Routers Market Size Was Valued at USD 673.99 Million in 2023, and is Projected to Reach USD 910.62 Million by 2032, Growing at a CAGR of 3.40% From 2024-2032.

Chlor-alkali Ion Exchange Membrane Market: Global Chlor-alkali Ion Exchange Membrane Market Size Was Valued at USD 483.83 Million in 2022, and is Projected to Reach USD 576.29 Million by 2030, Growing at a CAGR of 2.21% From 2023-2030.

Rotary Vane Vacuum Pumps Market: The Global Rotary Vane Vacuum Pumps Market Size Was Valued at USD 1216.2 Million in 2022 and is Projected to Reach USD 1690.23 Million by 2030, Growing at a CAGR of 4.20% From 2023-2030

Hydraulic Pump Market: Global Hydraulic Pump Market Size Was Valued at USD 10.1 Billion in 2022, and is Projected to Reach USD 14.04 Billion by 2030, Growing at a CAGR of 4.20% From 2023-2030.

Nuclear Moisture Separator Reheaters Market: Global Nuclear Moisture Separator Reheaters Market Size Was Valued at USD 802.38 Million in 2022, and is Projected to Reach USD 1176.3 Million by 2030, Growing at a CAGR of 4.90% From 2023-2030.

Palletizer Market: Global Palletizer Market was valued at USD 2.38 Billion in 2021 and is expected to reach USD 2.99 Billion by the year 2028, at a CAGR of 3.3%.

Quick-freezing Machine Market: Global Quick-freezing Machine Market Size Was Valued at USD 41.14 Billion in 2023, and is Projected to Reach USD 65.48 Billion by 2032, Growing at a CAGR of 5.30% From 2024-2032.

About Us:

Introspective Market Research is a premier global market research firm, leveraging big data and advanced analytics to provide strategic insights and consulting solutions that empower clients to anticipate future market dynamics. Our team of experts at IMR enables businesses to gain a comprehensive understanding of historical and current market trends, offering a clear vision for future developments.

Our strong professional network with industry-leading companies grants us access to critical market data, ensuring the generation of precise research data tables and the highest level of accuracy in market forecasting. Under the leadership of CEO Mrs. Swati Kalagate, who fosters a culture of excellence, we are committed to delivering high-quality data and supporting our clients in achieving their business goals.

The insights in our reports are derived from primary interviews with key executives of top companies in the relevant sectors. Our robust secondary data collection process includes extensive online and offline research, coupled with in-depth discussions with knowledgeable industry professionals and analysts.

Contact Us:

Canada Office

Introspective Market Research Private Limited, 138 Downes Street Unit 6203- M5E 0E4, Toronto, Canada.

APAC Office

Introspective Market Research Private Limited, Office No. 401, Saudamini Commercial Complex, Kothrud, Pune, India 411038

Ph no: +91-81800-96367 / +91-7410103736

Email: [email protected]

LinkedIn| Twitter| Facebook | Instagram

Ours Websites : https://introspectivemarketresearch.com | https://imrknowledgecluster.com/knowledge-cluster | https://imrtechsolutions.com | https://imrnewswire.com/ | https://marketnresearch.de |

Wall St Business News, Latest and Up-to-date Business Stories from Newsmakers of Tomorrow